Lineman’s pliers are a go-to hand tool for lots of tradesmen, especially electricians. Also called Kleins (for the brand-name), most combine a gripping jaw and side cutter. These pliers may seem like they’re all the same unless you know what you’re looking for. This post will walk you through the details to pick a good pair of lineman’s.

Lineman’s Features

Rivet

All lineman’s pliers are machined with a heavy-duty rivet. Quality construction ensures a smooth and consistent motion even after 10+ years of use. The location of the rivet is also important. Placing the rivet close to the cutter means it generates a greater force resulting in cleaner cuts.

Cutters

Cutters

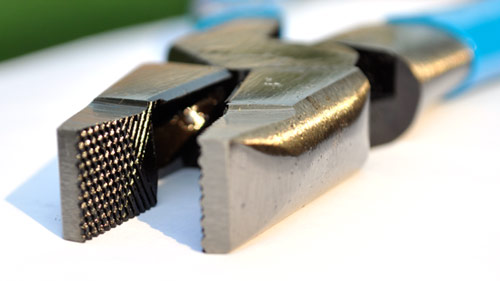

These pliers can be used for cutting wire, cable, nails and screws. You’ll find two different cutting edges: double sharp and knife-to-anvil.

- Double sharp features two sharp edges that meet in the middle. It’s easier for this style to become misaligned resulting in poor cutting.

- Knife-to-anvil cutting is just like it sounds. A sharp edge comes down on a small flat anvil- much more reliable.

Most cutters undergo heat treatment hardening via lasers or induction hardening resulting in a very durable blade.

Snub Nose

The snub nose is useful for gripping and bending heavy-gauge wire, sheet metal, etc. Look for cross-hatching on the jaws to provide better gripping traction. The squared off nose and flat side are also useful for making right angle bends.

Handles

The handles are often insulated to reduce (but not eliminate!) potential shock from live wires. Find a pair of lineman’s that feels comfortable and balanced in your hand.

Crusher / Crimper / Stripper

The opposite side of the rivet can add several different features depending on what you purchase. Some versions add a crushing area, crimping die, wire strippers or fish-tape pullers. I prefer the wire strippers because lineman’s are typically used for electrical projects.

CHANNELLOCK Lineman’s Pliers

CHANNELLOCK recently introduce a new 9.5″ lineman’s plier– model# 369. They’re made from high carbon steel and feature the knife-to-anvil side cutters. CHANNELLOCK moved the rivet for improved cutting leverage and topped it off with they’re cool blue comfort grips.

What do you think? What lineman’s do you recommend?

OK, I HAVE to have some of these now! My pliers are always coming apart and they don’t really grip. I love getting a recommendation from a friend. Now I can buy some with confidence. Thanks! Lisa~

Hey Lisa,

It’s important to know that the jaws have a small, intentional gap. They’re designed to grip (but not crush) wires and things of that nature. Paper-thin objects will still slip out.

I have a really old pair, that I use for tying rebar, the grips are long gone. Channel-lock is good quality, I have some wire cutters and they easily outlast the cheap ones by 4 or 5 times. I used them cutting wire lathe, removing almost all the stucco on our house, and they’re still sharp.

I have Channellocks, Knipex, Klein, Craftsman, and a pair that say nothing more than made in China. You won’t go wrong with the Channellocks. The pairs I have from Klein and Knipex have a softer and thicker rubber type coating on the handles that offer a more comfortable grip. I don’t really know how they will hold up over the years as wear and tear take their toll, but they seem to be holding up well.

Derek and PutnamEco, I really like the Channellocks so far but I haven’t had them very long. Overall, they put out a good product. Thanks for jumping in with your thoughts too!

I think lineman’s pliers really are one of the few “multitools” that do just as well as a single-duty tool in each of the combined functions. I’ve always been a fan of Channellock construction, because of the rivet joint and how strong and smooth it is on their pliers and cutters. I’m not as much of a fan of the smooth rubber-dipped tool handles that they, and others use. When hands get slick from wire-pulling gel, grease, or anything else, they’re not as grippy as the foam-rubber types of handle coverings. Honestly, though, I like to strip the Channellock handles and tape them up the way I like. Using friction tape (found in the electrical tape aisles), build up the handle wrap until it fits the palm of my hand more ergonomically. Here’s a picture of some Channellock 420’s I modified for work. The handle wrap has a couple swells and narrows to fit the fingers better, especially with fire gloves on.

http://img.photobucket.com/albums/v604/footrat/c9c71750.jpg

Those pliers look formidable, and I agree with William. The tape job really does make them more functional, also improving safety for people who might be working below you.